Setup and handling is quite simple. Loading material and unloading parts along with differing kinds of labor stocker, permit for an autonomous unattended operate unit.

The integration of milling and turning features in only one machine streamlines the manufacturing process and enables producers to achieve higher accuracy and quality.

The cookie is ready by GDPR cookie consent to record the user consent for the cookies while in the category "Functional".

Kern machines are known for their power to handle micro-machining tasks with unbelievable precision.

As CNC machining proceeds to evolve, it can Engage in a critical part in transforming the manufacturing landscape. People that embrace these enhancements will probably be well-positioned to lead from the competitive environment of modern manufacturing, driving productivity and innovation for years to come.

CNC machining seamlessly integrates with advanced manufacturing processes, serving for a cornerstone of precision engineering.

Speak to us currently to Learn the way AMT Machine Tools may help you accomplish your manufacturing ambitions successfully and website effectively.

Horizontal lathes are most common, nonetheless they could frequently be discovered by using a vertical spindle frequently called a Vertical Turret Lathe. You can also find Swiss-Design and style Lathes which have been used for smaller diameter workpieces and provide extreme accuracy.

Industry Applications: Perfect for demanding sectors that need incredibly restricted tolerances and reliability over lengthy durations.

Live tooling enhances the versatility of CNC lathes, making it achievable to finish complex parts in an individual setup. This functionality don't just speeds up production but additionally increases part accuracy by eliminating the need for various setups.

This integration of CAD and CAM software designed CNC machining much more available and popular in several industries. It removed the necessity for manual programming and presented a streamlined workflow from design to production.

This automation eliminates the need for manual intervention, lowering human mistake and expanding overall efficiency. With CNC machining, enthusiasts can improve their production workflows, cut down labor costs, and realize higher productivity amounts.

A strong most important spindle ensures that all types supply the appropriate speed plus the needed torque. Length involving centers, center top or swing diameter – The range of versions presents acceptable sizes For each and every software.

CNC machines present the accuracy and speed needed to develop functional prototypes that closely resemble the final item, permitting for a lot quicker design validation and much more effective iterations.

Scott Baio Then & Now!

Scott Baio Then & Now! Ross Bagley Then & Now!

Ross Bagley Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Daryl Hannah Then & Now!

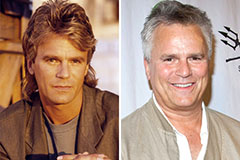

Daryl Hannah Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!